How to limit inrush current in switched-mode power supplies and LED drivers

Inrush current is the instantaneous peak current that flows into a power supply at switch-on. This article will explore the challenges of inrush current and how to use an NTC thermistor to as a current limiter.

In the case of most switched-mode AC-DC power supplies or LED drivers, the peak is a result of current flowing from the low impedance mains supply through to the smoothing capacitor on the DC side.

At switch-on, the capacitor is discharged and appears very briefly as a short-circuit as the supplied energy charges the capacitor. Once the capacitor becomes charged, typically 100 ms or less, the current flow reduces to a steady-state operating condition. Such peak current flows can cause damage to many components, reducing the reliability of the end-system.

Safety protection devices such as fuses and circuit breakers also have to be rated to accommodate the inrush current. In so doing, the peak current rating is typically significantly higher than the likely fault current, impairing the safety features operation in the case of an actual fault.

Inrush current peaks can also cause unexpected fuse ruptures and circuit breaker trips when switching on. Such annoyances result in the need to change a fuse at least, but if a circuit breaker trips, there’s a possibility other equipment will stop operating too. Inrush current peaks can also damage switch contacts, and in extreme cases, weld the switch contacts surfaces together.

The difference between the inrush current and the steady-state current can be significant. For example, a 250-watt AC-DC power supply might draw approximately 1 A during regular operation, but the inrush current might be as high as 30 A.

DC-DC converters can also experience inrush current challenges. When powered by a DC battery, which like the mains supply is a low impedance source, the current it can supply is considerable. Also, smoothing, reservoir, or hold-up electrolytic capacitors on the output need charging at switch-on, presenting a short-circuit until charged.

Inrush current is also of concern for equipment that has inductive loads, such as motors used for air-conditioning equipment. Often larger inductive loads use a more active form of inrush current limiting involving relays and other switchgear.

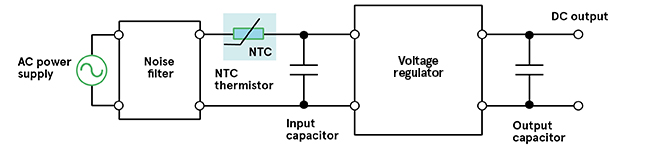

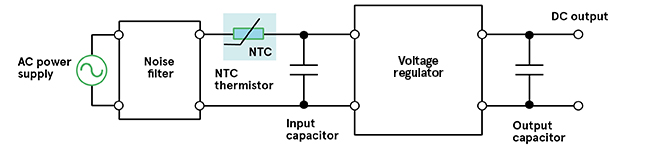

Figure 1: The input circuit of a typical AC-DC power supply

How to use NTC thermistors to limit inrush current

A popular and cost-effective technique used to limit inrush current in AC-DC power supplies is to include a negative temperature coefficient (NTC) thermistor in the mains supply line, immediately after the mains electromagnetic interference filter.

An NTC thermistor has a high resistance when cold, and low resistance when hot. As a result, NTC thermistors suit a variety of temperature monitoring and sensing applications, but some are manufactured specifically for inrush current limiting purposes.

At switch-on, the high resistance of the thermistor appears in series with the smoothing capacitor, limiting the maximum current. The current passing through the thermistor causes it to warm up, termed self-heating, and its resistance decreases. In this way, the peak inrush current is limited. Thermistor resistance values are typically specified at 25°C.

When selecting a thermistor, the steady-state operating temperature, likely peak current flow and steady-state or average current flow are all essential criteria. Thermistors are a popular choice but can impact the power efficiency attributes of a power supply.

In typical operation, the thermistor resistance is not zero, but depending on the device, maybe a few ohms or less. Designed into the power supply calculations during the development of the power supply, the thermistors 'on' resistance will not impact operation, but it does result in an energy loss, manifesting itself as heat. The energy loss from the thermistor, together with other sources of energy loss contribute to reducing the overall conversion efficiency of the power supply.

Often a power supply design team will browse potential thermistors from different suppliers and seek to balance thermistor inrush current characteristics against the impact on power supply efficiency.

An example NTC thermistor suitable for inrush current limiting in AC-DC power supplies is the TDK B57464S109M. This thermistor has a nominal resistance of 1 Ω at 25 °C, has a maximum current rating of 20 A, and is constructed in a leaded coated disc package. It can be used in a series connection up to 265 Vrms. The minimum resistance at maximum current is 0.018 Ω, and the maximum power capability is 6.7 W.

NTC thermistors provide a compact, passive, low-cost way of protecting power supplies and connected equipment from the effects of damaging inrush currents. If you need advice on selecting an NTC thermistor for your power design, our power specialists are on hand to help.