Pressure sensors: 8 building automation applications

As urban population density increases, larger buildings are becoming increasingly commonplace, and controlling their internal environment accurately is a challenge for designers and operations staff alike. In addition, rising environmental concerns and tightening regulations have made minimising resources used to heat and cool buildings a serious consideration.

The business of building automation integrates heating, ventilation, air conditioning and refrigeration (HVACR), with control interfaces and monitoring systems – all with the help of pressure sensors.

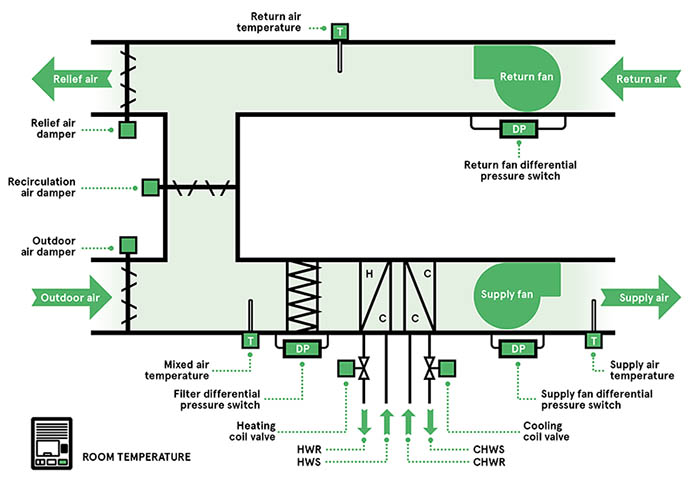

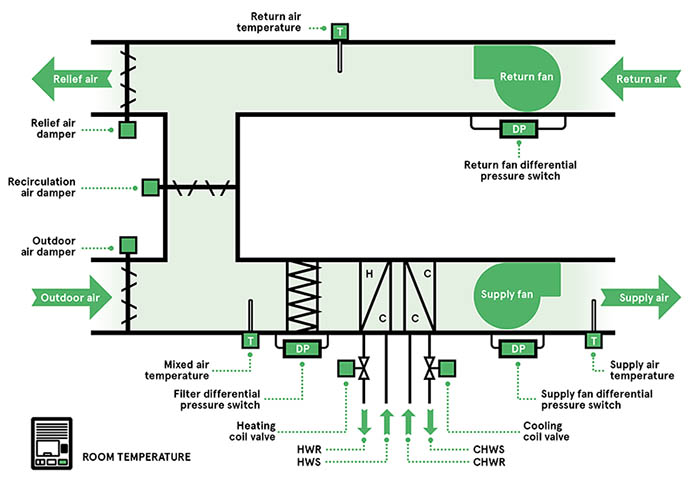

A representation of a typical HVAC system

1. Monitoring air filters

The air filter is a critical part of any HVAC system, and it needs to operate efficiently at all times. By using a differential pressure sensor to measure the pressure on both sides of the filter (see diagram below), the building automation system can monitor the airflow at all times.

As airflow reduces over time it may indicate the filter needs replacing or cleaning. If it isn’t replaced, the system may need to use more energy to restore the airflow to required levels, which also places additional wear on other components in the system.

A differential pressure sensor measuring airflow through a filter

2. Minimising fan power use

The flow of air in an HVAC system needs to be kept within specific parameters in order to maintain a safe and comfortable living or working environment. Fans force the air through ducts in the system to keep it circulating. A network of differential pressure sensors fitted across the air ducts monitors how the air is flowing throughout and allows the system to regulate each fan’s speed and keep energy costs to a minimum.

3. Maintaining relative duct pressure levels

Differential pressure sensors are also used to measure the relative pressure differences between duct air and room air. Air pressure differences can cause various issues in a building, normally attributed to either a positive or negative air pressure difference. For example, a negative air pressure in one part of a building will cause air currents, as the relatively higher pressures find their way into the low pressure areas. An imbalance can lead to doors or windows being difficult to open or close, or a loss of heated/cooled air which leads to higher energy costs. By measuring the relative air pressure differences around a building’s HVAC system these issues can be avoided.

Measuring the pressure inside a duct, relative to a room or open space, can be achieved using a differential pressure sensor with one side open to the ambient air in the room. Typically, the pressures being measured are relatively low, so the sensor would be specified to operate over a range of around ±50 Pa (pascals).

4. Improving heat exchange efficiency

Building management, control and automation systems are able to control the temperature and humidity of a room thanks to the feedback their sensors provide.

Pressure sensors that measure the amount of relative air pressure in a room are particularly important, which is generally normalised to 1 atmosphere (ATM). Using a pressure sensor to monitor the air pressure in a room over time can determine whether there are sealant leaks around doors and windows, which would lead to heat (energy) losses.

H and cooling systems use pumps to compress fluids for heat exchange, and these have pressure sensors positioned on the high side and low side of the compressor to ensure the pressure difference is maintained for optimum performance. The type of sensor used here might include a differential pressure sensor with a scale of 0 to 25 bar.

5. Monitoring variable air volume heating systems

Ventilation is an important aspect of HVAC systems, which involves closely monitoring and controlling the volume of air flowing into a room. If the heating system uses a Variable Air Volume (VAV) configuration (as opposed to a Constant Air Volume, or CAV system) the temperature is maintained by varying the temperature of the air volume of air flowing into the room, rather than the temperature of the air. In this case, differential pressure sensors are used to measure the volume of air, and would be specified with a range of around 0 to 360 Pa. The feedback provided by the sensor allows the building control system to open or close dampers, allowing more or less air to flow into a room.

6. Automated safety systems

Building management controllers can use pressure sensors to directly control aspects of the HVAC system, often in the form of a differential pressure sensor that operates as a switch. This allows the system to automatically turn devices on or off when it measures a pressure difference that is under or over set limits, potentially preventing wider damage to the system or sudden environmental changes within the building.

These sensors will typically be specified to operate over a range of 0.1 to 4.00 In H2O, and they feature a spring-loaded diaphragm that actuates two switches, one to detect over-pressure and one to detect under-pressure. The limits on each state will span a small excursion of the full-scale range and be relative to the sensor’s total span (see diagram below). Contacts can be rated up to 240VAC, with an excess of 1 million switching operations.

7. Maintaining gas pressure in pneumatics

Relative pressure sensors are used to measure the pressure of sub-systems based on hydraulic or pneumatic operating principles in HVAC systems. These can take the form of gases or liquids used in the heating or cooling process, and ensure the sub-systems are ready for immediate use if required.

Pneumatic pressure sensors can operate over a wide range of pressures, up to 600 bar if necessary, and are capable of operating while fully submerged in depths of 100 metres or more.

8. Monitoring dangerous chemicals

Ammonia is used as a coolant in HVAC and refrigeration systems, but could cause significant damage and danger to people in the event of a leak. However, relative pressure sensors can be used to monitor the pressure of the ammonia as it passes through the system, ensuring it stays within acceptable limits. This is a task where differential pressure sensors able to measure differences from 6.0 psi on the low pressure side to 175 psi on the high pressure side are used.

Building monitoring, control and automation systems harness the power and benefits of HVACR equipment, which in turn relies heavily on pressure sensors to function efficiently.

As building and home automation technologies and concepts become increasingly applicable to all homes, not just large business structures, pressure sensors will continue to play a central role in controlling the environments we live in.

What else are pressure sensors used for?

Find out more in our articles on applications in automotive, building automation, consumer and wearables, medical and industrial applications.

Pressure sensors: 10 innovative automotive applications.

Pressure sensors: 8 life-saving medical applications.

Pressure sensors: 11 life-enhancing consumer applications.

Pressure sensors: 3 applications enabling smart factories in Industry 4.0.

Looking for more on pressure sensor technology? Check out the further chapters of this guide below, or if you're pressed for time you can download it in a PDF format here.