Automotive Ethernet

The electronic future: half the cost of vehicles to be electronic by 2030

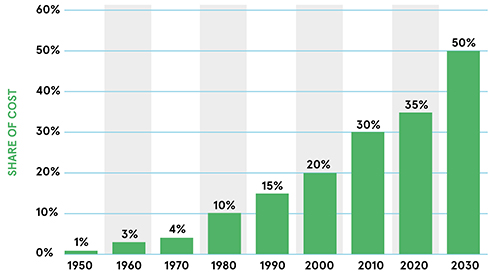

Figure 1: Electrical content formans an increasing part of modern vehicle costs (Source: Statista) |

The drive for greater economy in automotive design is leading to the replacement of mechanical and hydraulic systems with electronic alternatives that are more efficient, smaller and lighter – and more reliable. Each of these devices has to be interfaced into the system, resulting in many vehicles today having upwards of 100 electronic control units (ECUs) onboard. In fact, according to market research company Statista, electronics currently form around one-third of the cost of a vehicle, with this expected to rise to one-half within the next decade (see right).

Increased focus on the road: the rise of the multi-camera car

Recent trends in vehicle design include the addition of more cameras. In many jurisdictions reversing cameras are now required by law. And many manufacturers are adding forward-facing cameras to identify objects, maintain distance between vehicles and read speed signs. Plus, further cameras throughout can assist in automated parking and even ensure the driver is paying attention. As a result, modern vehicles can contain 10 or more cameras, all gathering and streaming data.

The move to automotive Ethernet

In general, each of these ECUs exist as a modular stand-alone unit which require the ability to communicate with each other and with a central system, like the sophisticated infotainment systems in many modern vehicles.

There have been a number of protocols developed for automotive networking over the years including local interconnect network (LIN) and 1Mbit/s controller area network (CAN). And, while these are still in use, with today’s multi-ECU / multi-camera vehicles, their usefulness (like their bandwidth) is limited.

Other protocols including 10Mbit/s media-oriented systems transport (MOST) and FlexRay were developed to provide greater throughput, but they haven’t been widely adopted.

Automotive protocols

Both vehicle manufacturers and their suppliers were keen to move away from different bus protocols to a more universal arrangement for in-vehicle networking (IVN). The chosen protocol should support faster data rates and provide lower latency than existing solutions. Additionally, it should be able to reduce the physical medium – the cabling used for transmission – to reduce cost as well as improving efficiency by lowering vehicle weight. The protocol will also need to be implemented securely. This is becoming an increasingly important consideration as vehicles become more connected to the environment around them and eventually to other vehicles.

Collectively, the automotive industry is moving towards Ethernet as the preferred solution for IVN. Ethernet benefits from being a highly-used protocol in commercial, industrial and residential applications. This means there’s a wide understanding of the technology and lots of components, software, tools and design resources available which will speed up the design process and reduce cost.

The challenges of automotive Ethernet

However, implementing Ethernet in vehicles brings a number of challenges that are simply not present in current implementations of the Ethernet protocol. With their constrained spaces and prevalence of relatively high-power electronic systems, operation within a vehicle means that networking components and cabling have to withstand elevated temperatures and significant electro-static discharge (ESD) events and electro-magnetic interference (EMI). And on top of that, there are other issues including vibration, impact, cold, dirt, aggressive fluids and voltage fluctuations to contend with.

While there are many components available for Ethernet, they are not immediately suitable for the automotive Ethernet protocol. Most components destined for automotive use are subjected to a series of stringent electrical, lifetime and reliability tests. These tests will qualify components to one of the five grades of AEC-Q100. (Grade 0 is for drivetrain components and is the most stringent [-40°C to +150°C] while lower levels for Grades 3 and 4 are closely matched to industrial and commercial levels).

Ethernet is a 4-wire protocol which adds cost to the backbone and weight to the vehicle, thus decreasing fuel efficiency. But it does address many of the challenges of fibre-optic that made MOST an expensive and relatively unpopular solution. Although, perhaps the largest area to be addressed in developing an automotive Ethernet protocol is that of latency.

Ethernet is essentially a packet-based protocol that uses carrier-sense multiple access with collision detection (CSMA/CD) to allow multiple devices to access a single backbone without transmitting over each other. However, as this forces nodes to ‘back off’ for a random time, the protocol is not deterministic. While this is not an issue for many applications, including data transfer in commercial and domestic scenarios, if it delays the transmission of an urgent safety alert in a vehicle, that could pose a significant problem.

The different Ethernet standards

Many derivatives of the main Ethernet standard have been developed. Standards such as IEEE 100BASE-T1 (IEEE802.3bw) offer 100Mbit/s at a clock frequency of 66 MHz while IEEE 1000BASE-T1 (IEE 802.3bp) stretches this to 1Gbit/s at 600 MHz – a level that is expected to meet the needs of the automotive industry for some time to come.

The standards will co-exist, at least to an extent, and soon vehicles are expected to contain around a dozen 100Mbit/s lines and a further half dozen 1Gbit/s lines to suit the needs of the various systems and sensors.

The next big step forward is a new network technology under the IEEE 802.3cg standard that is known as 10BASE-T1S or 10SPE (10 Mbps single pair Ethernet). This delivers collision free, deterministic transmission on a multi-drop network. The physical layer collision avoidance (PLCA) implemented within the protocol ensures that all of the 10Mbit/s bandwidth is utilised. 10BASET1-S also includes an arbitration scheme that guarantees each and every node access to the media within a deterministic time, which is essential to the operation of safety-critical systems. Of course, halving the number of conductors makes the cabling lighter, more flexible and lowers costs – all desirable attributes.

Choosing the right components for automotive Ethernet

The selection of system elements is very important, given how critical automotive Ethernet is to the function and safety of the vehicle. The OPEN (‘one pair Ethernet’) Alliance has developed many standards including the electrical performance parameters for the network physical layer for speeds up to 1Gbit/s.

When selecting a cable for automotive Ethernet, the critical parameters include characteristic impedance (100 +/-10 Ohms), insertion loss, return loss and conversion mode. While crosstalk has been an issue with previous Ethernet installations, as the OPEN standards use a single pair, crosstalk is completely eliminated.

The specification of connectors is equally important and the primary areas for consideration are the mechanical parameters (mating force / cycles, retention force, wire retention), electrical data (contact resistance and aging, voltage, current), environmental information (shock, vibration, temperature) and the materials from which the connector is made (body, seals and contacts).

Development of connectors is just one way that Ethernet is being adapted to suit and survive the automotive environment. New, 20+ Gigabyte-capable connectors that are suited to general automotive as well as commercial vehicles and construction / agriculture are now available. These connectors are smaller in pitch which saves valuable PCB space which is always a challenge for designers. To suit the rugged automotive environment, the cables are welded to the terminals, not crimped, which gives a more robust termination and better signal integrity. In some cases, the terminals are designed to accept shielded twisted pair (STP) as well as Twinax wires, which allows designers to upgrade to faster Ethernet while maintaining the same interface.

There are many options available to designers for connectors specifically tailored to the automotive environment. Scalable designs offer between 1 and 7 contacts with mechanical and colour coding to prevent mis-insertion. The mechanically robust, fine pitch solutions offer a CCPA that provides a secondary lock for the contact carrier.

Transformers and common-mode chokes that allow Ethernet devices to access the physical layer and provide EMC filtering are crucially important to Ethernet designers. Again, size and robustness are critical here – solutions are available from suppliers that are involved in the OPEN Alliance. Selecting these solutions means that designers can be confident about their performance and compatibility, not least because they have been qualified to AEC-Q200 and tested with PHY partners.

The modules that sit on the in-vehicle Ethernet network are also susceptible to potentially damaging spikes, so designers are required to provide protection to ensure the longevity of important modules such as ECUs. Varistors are typically used to protect Ethernet, although these have typically been relatively large devices (often pin-in-hole) that had significant capacitance that degraded signal integrity, especially at higher frequencies. Recent advances have delivered a new breed of miniaturised multilayer varistors in tiny IEC 1005 (1.0 x 0.5 x 0.5 mm) surface mount packages. These devices are AEC-Q200 qualified and offer extremely low capacitance of around a picofarad which, along with their 150°C rating, makes them ideal for automotive Ethernet applications such as 1000BASE-T1.

Summary

Automotive Ethernet offers a viable and unifying technology to replace previous automotive networking standards and deliver the bandwidth needed for technology-laden vehicles. Not only does it have the throughput needed today, it offers future potential to allow the inclusion of higher resolution cameras and vehicle-to-vehicle communications.

One of the great benefits of Ethernet is that it’s widely implemented in commercial, industrial and domestic applications. As a result, there’s an extensive knowledge base in place and development tools and software are readily available. In an automotive environment, designers are faced with harsh conditions including elevated temperatures and vibration. As, up until now, Ethernet has been primarily deployed in a static office environment, these have not been concerns.

To address these needs, along with the requirement for addressing electrical noise, engineers need to be careful not to overlook the importance of components such as connectors, chokes, transformers and varistors. These components play a critical part in the reliability and functionality of automotive Ethernet systems, and the market is developing rapidly to meet increasing demands for components specifically engineered and qualified for this use.

Below we’ve highlighted our leading suppliers of components for automotive Ethernet.

If you require advice on selecting the right components for your design, our technical specialists are on hand to help.

Applications

- Powertrain and EV/HV/PHEVs

- Comfort infotainment, and safety

- Communications and connectivity

- Lighting

Engineering Services

Ready to start the engine of your automotive design?

Our automotive specialists are on hand to provide technical and product support you need.

Focus magazine

Automotive design: accelerating innovation

This edition of Focus magazine addresses these challenges from each perspective.