Deciphering datasheets for medical PSUs

Specifying medical power supplies can be particularly challenging because of the standards and jargon surrounding this application. This field is heavily regulated, but the regulations differ between territories, and compliance is strict.

Let’s take a closer look at some of the things to look out for on data sheets, using the Bel Power MBC300 series of medical power supplies as an example.

First, check that the supply you’re considering meets design requirements.

You should have an idea of your application’s power requirements, the supply voltage, the likely usage scenarios, and any environmental factors that may affect selection. Most of these criteria can easily be checked off against the power supply’s data sheets. So far, so good, but there are a couple of non-straightforward points to consider here.

Ambient temperature and heat transfer are particularly important to power supply specification, so make sure you understand exactly how the power supply will be cooled when it’s in situ. It could be purely convection cooled, that is, there is no fan and the power supply emits waste heat into the ambient air by convection. Or it could be cooled by forced air cooling, that is, a fan forces air flow across the power supply at a certain minimum rate.

If cooling is insufficient, this affects the performance of the power supply’s components, and the output power will reduce below optimum levels. How much the output power will drop is typically illustrated by derating curves on the data sheet, like the ones below for the Bel Power MBC300 series.

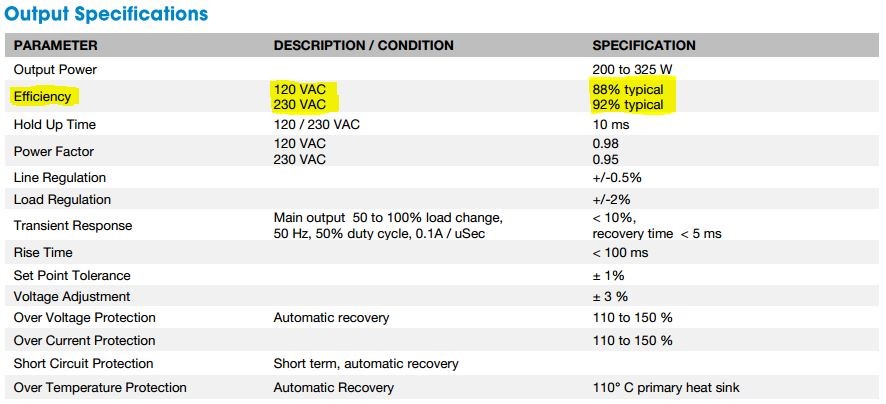

The other criterion that isn’t always straightforward to understand is the power supply’s efficiency. This is typically stated as a single headline figure, but be aware that this represents the best case scenario – the efficiency you can expect under optimum operating conditions. The actual efficiency you’ll be able to achieve depends on several factors.

Most important is the load condition. Efficiency is the ratio of the output power to the input power, expressed as a percentage. If the output power is reduced, perhaps if the load drops below the power supply’s full-load condition, the efficiency will reduce (since the input power is the same). Under low-load or no-load conditions, the efficiency is drastically lower.

Supply voltage also has a marked effect – power supplies are less efficient at lower supply voltages because they have to draw more current to supply the same amount of power, which leads to more resistive losses in the power supply’s components. This is good news for Europe, where the supply voltage is 240V, bad news if the power supply is to be used in the US and Japan where the supply voltage is 110V or less. This is not to be taken lightly – the difference for the Bel Power MBC300 series is a drop of four percentage points for European versus USA voltages.

Second, check that the supply you’re considering meets the relevant standards and regulations.

The main standard to be aware of for medical devices is IEC/EN60601-1.

IEC/EN60601-1 describes the levels of protection that are required to protect patients and operators from electric shock. Protection methods (means of protection, or MOPs) are divided into MOOP (means of operator protection) and MOPP (means of patient protection). The idea is that all applications will provide at least one MOOP and one MOPP, but some will need two MOPPs.

Examples of MOPs might be a certain level of isolation, creepage, or insulation. Most medical power supplies (like the Bel Power MBC 300 series) will have two MOPPs as standard, and this should be stated on the data sheet. Note that it’s often practical to use a two-MOPP power supply even if a one-MOPP supply would do, largely because of the resulting ease in certification.

Beware of so-called ‘medical’ power supplies that do not explicitly state the level of MOP they provide on data sheets – it usually means they won’t meet IEC/EN60601-1. Manufacturers sometimes say “approved for medical use” when the power supply is intended for use in in-vitro diagnostic devices (such as lab equipment), which are outside the scope of IEC/EN60601-1 as they do not come into contact with patients. In this case, conformity to IEC/EN 60950 (the same standard used for anything connected to the mains) is enough protection.

Aside from MOP, the other key thing to check the data sheets for is leakage current, which IEC/EN60601-1 restricts to 500µA. However, note that the USA has additional standards in place for the leakage current of devices for patient care. The USA limit is tighter than IEC/EN60601-1, at 300µA for Class 1 (power supplies that are Earthed), or 150µA for Class 2 (those with a double insulation layer instead of an Earth connection). Again, most bona fide medical power supplies will meet both these criteria and it should say so on the data sheet.

In summary, getting the right information from a medical power supply data sheet should be straightforward enough if you know what to look out for. If you are at all unsure our team of technical specialists is always on hand to help. Get in touch in your local language by clicking the Ask an Expert button to the right of this post.

Ask an expert

Have a question? Our regional technical specialists are on hand to help.