Ethernet magnetics – Discrete or integrated?

If you’re adding wired Ethernet to a design, you will of course have to consider magnetics. All Ethernet enabled equipment has to include magnetics as the Ethernet specification for 10/100/1000BASE-T networks requires a certain level of galvanic isolation from the cable. 1:1 Transformers are usually used to meet this requirement as they also provide any required DC biasing (say when the nodes are powered from different sources, which may result in a ground offset between the transmitting and receiving equipment). Transformers also provide common mode rejection which is useful for noise attenuation between the PHY device (transceiver IC) and the physical medium (cable).

There are, broadly, two options for Ethernet magnetics that are widely used today. The first is to add an Ethernet magnetics module to your design’s PCB, between the PHY chip and the connector jack. The second is to use a jack with the magnetics integrated into its housing. As you’d expect, both options have advantages and disadvantages.

Discrete Ethernet transformer modules with multiple channels in SMT packaging are widely available and usually incorporate a common mode choke on each channel for noise mitigation purposes, as 10Mbps connections and faster need this to pass FCC testing. Discrete magnetics modules are often used in cost-sensitive applications as they can be less expensive than the integrated equivalent. They also help maximise the system’s protection from electrostatic discharge (ESD) as this design allows greater physical separation between the devices in the Ethernet front end.

The Bel Magnetics S558-5999-Q2-F is a dual channel 1000BASE-T LAN magnetics module while the M8-F (also pictured bottom left) is single channel

The Ethernet standard is clear on the properties the magnetics need to have. For example, a transformer for a 100BASE-T connection is required to have an inductance value of at least 350µH when a DC bias of 8mA is applied. So all magnetics modules designed for Ethernet isolation will have this in common.

Things to look out for when choosing a discrete magnetics module include the common mode rejection figures, which refer to the ability to reject noise picked up by the cable and/or produced by any impedance mismatches. You may also compare modules based on figures such as the insertion loss at different frequencies (effectively the loss of energy between the input and the output) and return loss at different frequencies (loss of energy due to impedance matching).

Another consideration is crosstalk between transmit and receive channels, which should be minimised – some modules feature shielding between the channels which can provide extra protection. Consider also the likely temperatures in your application, as devices are available with different operating temperature ranges. For example, the Bel Magnetics range come in 0 to 70°C or

-40 to +85°C versions.

Checking the literature for the PHY chip in your design will often reveal the manufacturer’s recommendations based on specific modules they have tested alongside their own chip, so that represents a good place to start.

Toroidal transformers

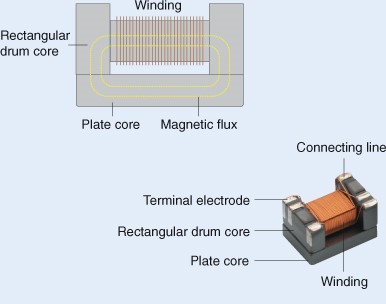

TDK has a slightly unusual take on transformers for Ethernet magnetics. The company wanted to use toroidal (doughnut-shaped) transformers in this application as they have excellent leakage flux characteristics, but since toroidal transformers have to be hand-wound, the manufacturing tolerances are typically too loose. TDK borrowed an idea it already uses for its SMD common mode choke coils – it uses machine winding to add coils to a drum core, then combines it with a flat plate core, making the toroidal shape. The result is the ALT series.

The structure of the TDK ALT series – the coils are wound by machine onto a rectangular drum core and combined with a plate core to make the desired toroidal shape

The ALT series offers much better uniformity compared to hand wound devices, and it can provide comparable performance to equivalent products at a much smaller footprint. These devices are used discretely alongside separate common mode chokes but can save 40 to 60% of the board space that a comparable module uses.

Integrated Connector Modules

As an alternative to discrete magnetics modules, Ethernet connectors with all the required magnetics integrated into their housing have been available for some time. These integrated connector modules (ICMs) can offer a quicker and easier design process, lower component count, lower assembly cost and often, smaller footprints than using a separate module. Reliability is improved as there are fewer solder connections in the design. However, if the connector fails during production test, there may be a higher cost associated with reworking than with a discrete module.

The market leader for ICMs is Bel Stewart’s MagJack range, which comes in 10/100Base-T to 10GBase-T and PoE (plus) versions

Inside the connector housing, the cores are relatively small and close together which can result in relatively high levels of crosstalk. Most modern devices feature shielding for precisely this purpose. Other EMI considerations include keeping the PCB tracks between the PHY and the ICM as short as possible. In fact, since track lengths can be kept shorter when using an ICM compared to a discrete module, ICMs have a slight advantage here. As stated above though, these short distances can cause problems with ESD susceptibility.

If you need help choosing between discrete and ICM Ethernet magnetics, get in touch with our technical specialists on our Ask an Expert page.

Ask an expert

Have a question? Our regional technical specialists are on hand to help.