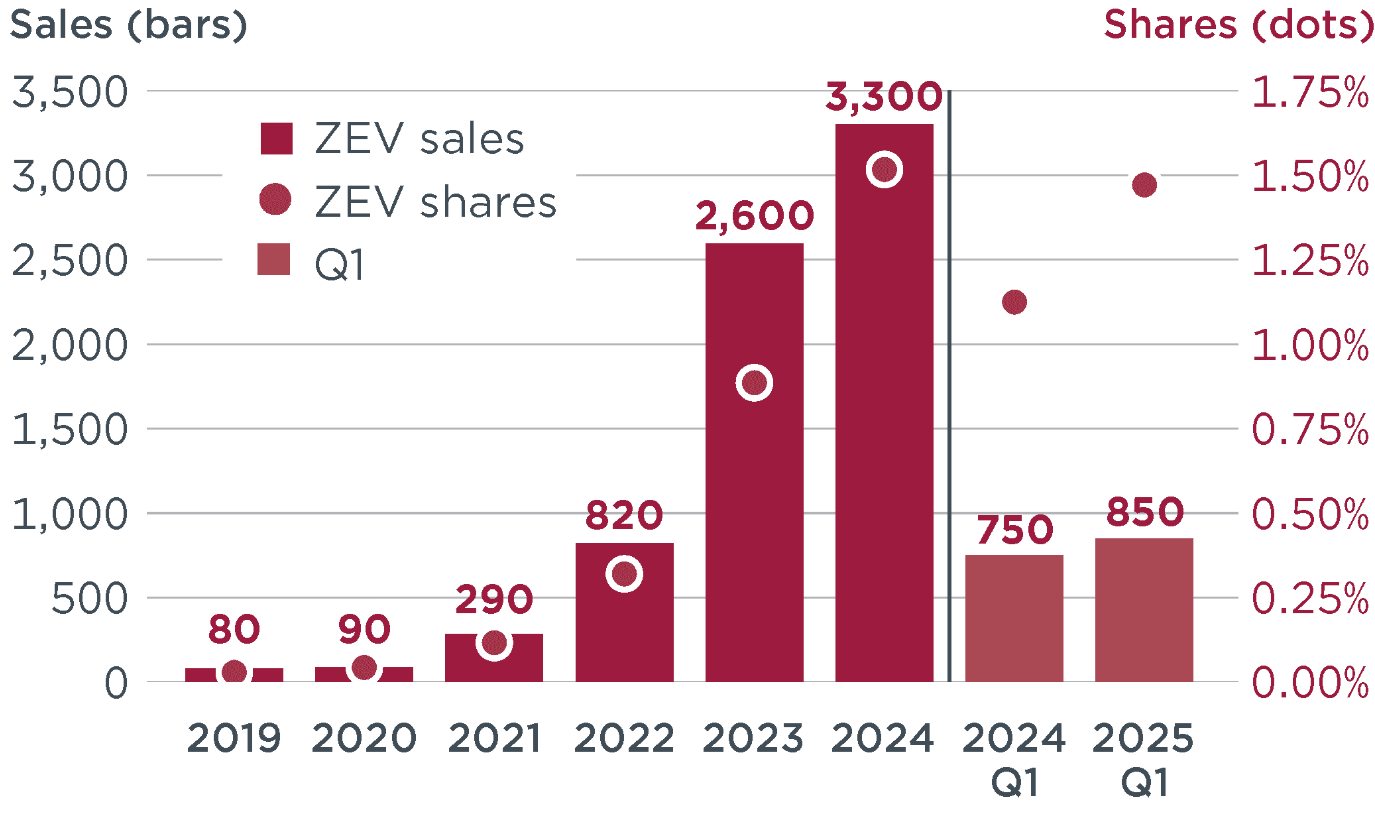

Sales shares of zero-emission heavy trucks in select EU Member States (Source: The ICCT)

Electrifying Industrial Vehicles: Engineering for Heavy-Duty Power

The electrification of transport is often discussed in the context of passenger electric vehicles. Yet beyond cars and vans lies a much larger, more demanding opportunity: heavy-duty industrial vehicles. Mining trucks, construction machinery, port vehicles, and industrial HGVs underpin global supply chains and infrastructure, but remain heavily dependent on diesel power.

Pressure to decarbonise these vehicles is intensifying. Emissions regulations, corporate sustainability targets, rising fuel costs, and local air-quality concerns are converging to make electrification a practical and increasingly unavoidable design consideration. At the same time, operators are focused on reducing noise, improving efficiency, and lowering total cost of ownership.

Electrifying industrial vehicles requires a fundamentally different engineering approach from passenger EV design, particularly in power electronics and system-level energy management.

Why Industrial Electrification Plays by Different Rules

Passenger electric vehicles are typically designed around relatively predictable operating patterns, established charging infrastructure, and duty cycles that include long periods of rest. Industrial vehicles operate under very different conditions.

Heavy-duty platforms are expected to deliver continuous, mission-critical performance in harsh environments, often far from conventional grid infrastructure. They must tolerate extreme temperatures, vibration, dust, and moisture, while maintaining high availability and minimal downtime. Operating profiles are highly variable, with frequent peak-load events, rapid changes in power demand, and limited opportunities for extended charging.

Crucially, these vehicles are also tightly coupled to productivity. Any interruption to operation has a direct impact on output and cost, making reliability, serviceability, and intelligent energy management as important as raw performance.

In this context, industrial vehicle electrification places very different demands on system design than passenger EV architectures. Designers face specific challenges in power delivery and power management, driven by the need to supply very high levels of instantaneous and continuous power across highly variable duty cycles. These challenges become especially pronounced as power levels scale into the hundreds of kilowatts and beyond.

Power Levels That Redefine Design Constraints

Industrial vehicles span a wide spectrum of power requirements. Light industrial platforms may operate at a few hundred kilowatts, while large mining haul trucks or heavy construction equipment can demand power in the megawatt range.

At these levels, every design decision has system-wide implications. High-current distribution, voltage selection, isolation, and fault protection all become critical considerations. Losses that would be negligible in smaller systems quickly translate into significant heat, efficiency penalties, and reduced operating range.

Power scaling, therefore, depends on system architectures that can grow modularly while maintaining efficiency, reliability, and serviceability.

Modular Power Electronics as a Scaling Strategy

One of the most effective responses to rising power demands is modularity. Rather than relying on monolithic converters, designers are increasingly adopting modular inverter architectures that can be scaled, serviced, and upgraded more easily. This approach allows platforms to flex across different vehicle classes, while introducing redundancy that improves uptime and simplifies maintenance strategies. By distributing power conversion across validated building blocks, modular architectures also support more manageable thermal design and faster development cycles, reducing risk as systems scale.

This strategy aligns well with the evolving semiconductor landscape, where leading suppliers continue to deliver power devices optimised for high-power, high-reliability applications.

Designing for Extreme Duty Cycles

Industrial vehicles rarely operate under gentle conditions. Load profiles are highly dynamic, with frequent acceleration, regenerative braking, and peak-power events. Ambient temperatures can be extreme, and vibration, dust, and moisture are constant concerns.

These operating conditions place sustained stress on power electronics, energy storage systems, and interconnects. Designing for extreme duty cycles requires a holistic view of electrical, thermal, and mechanical performance. Thermal management, in particular, becomes a defining challenge. Continuous high-power operation demands advanced cooling strategies, efficient heat paths, and system-level optimisation to prevent hotspots and extend component lifetime.

Heat: The Silent Constraint

As power levels increase, heat becomes one of the most limiting factors in industrial vehicle electrification. Losses accumulate across inverters, converters, cabling, and energy storage systems, and insufficient thermal management can quickly erode efficiency and reliability.

Effective thermal design is a system-level exercise, shaped as much by semiconductor choice and packaging as by cooling architecture and enclosure design. In heavy-duty vehicles, thermal considerations often influence mechanical layout, service access, and vehicle weight. Managing heat efficiently is therefore central to achieving both performance and durability.

Charging Beyond the Conventional Grid

Unlike passenger EVs, industrial vehicles are often deployed in locations where the electrical grid was never designed to support megawatt-scale charging. Mines, ports, construction sites, and logistics hubs may face limited grid capacity or highly variable loads.

This reality is driving interest in local energy solutions that reduce dependence on grid upgrades. On-site energy storage, renewable generation, and dedicated charging infrastructure are increasingly being integrated into industrial electrification strategies. Rather than treating charging as a standalone function, designers are viewing it as part of a broader energy ecosystem.

The Rise of DC Microgrids in Industrial Sites

DC microgrids are emerging as a practical way to manage energy flow in industrial environments. By integrating local generation, stationary storage, and vehicle charging within a controlled DC architecture, operators can smooth peak demand, improve efficiency, and enhance resilience.

For vehicle designers, this shift has important implications. Vehicles must interface seamlessly with site-level energy systems, support high-power DC charging, and communicate effectively with energy management platforms. The boundary between vehicle, charger, and infrastructure is becoming increasingly blurred.

Technology

Power: designing solutions with power at the core

We provide you with the right insights and expertise when you need it most, so you can make the right decisions for your product, and your business.

Power application

Powering EV Charging

EV charging is one of the fastest growing subsegments in the automotive industry, with the charging infrastructure market in Europe alone forecast to grow at a compound annual growth rate (CAGR) of more than 30% from now until 2030.

See how Avnet Silica is supporting the latest innovative EV solutions. From the forecourt to the cloud, we complement your skillset to get your EV charging requirements deployed faster, better and stronger.

SEE EV OVERVIEWIntelligence as a System Requirement

As electrified industrial vehicles become more powerful and interconnected, intelligence becomes essential. Advanced control systems are needed to orchestrate power flow between traction systems, auxiliary loads, energy storage, and charging interfaces. Intelligent energy management enables more effective use of available power, while helping to reduce peak demand and overall operating costs. At the same time, tighter integration of monitoring and control functions supports predictive maintenance and earlier fault detection, improving both safety and system reliability as power levels and system complexity increase.

These capabilities rely on close integration between hardware, software, and system-level design.

From Components to Ecosystems

Electrifying heavy-duty industrial vehicles is not a single-component challenge. It requires coordination across semiconductors, power modules, control electronics, thermal solutions, energy storage, and infrastructure.

This complexity is driving closer collaboration across the value chain. Designers increasingly rely on partners who understand not only individual components, but also how they interact within complete systems.

Access to a broad portfolio of technologies, combined with system-level expertise and supply-chain resilience, is rapidly becoming a competitive advantage.

Enabling Heavy-Duty Electrification at Scale

Electrifying industrial vehicles offers a major opportunity to reduce emissions, improve efficiency, and modernise heavy industry. Achieving it at scale demands new thinking around power, heat, and energy integration.

As a leading distributor and technology partner, Avnet Silica works closely with leading semiconductor suppliers and system innovators to support this transition. By combining access to advanced technologies with deep application insight, Avnet Silica helps engineers navigate the complexity of heavy-duty electrification — from early concept through to deployment.

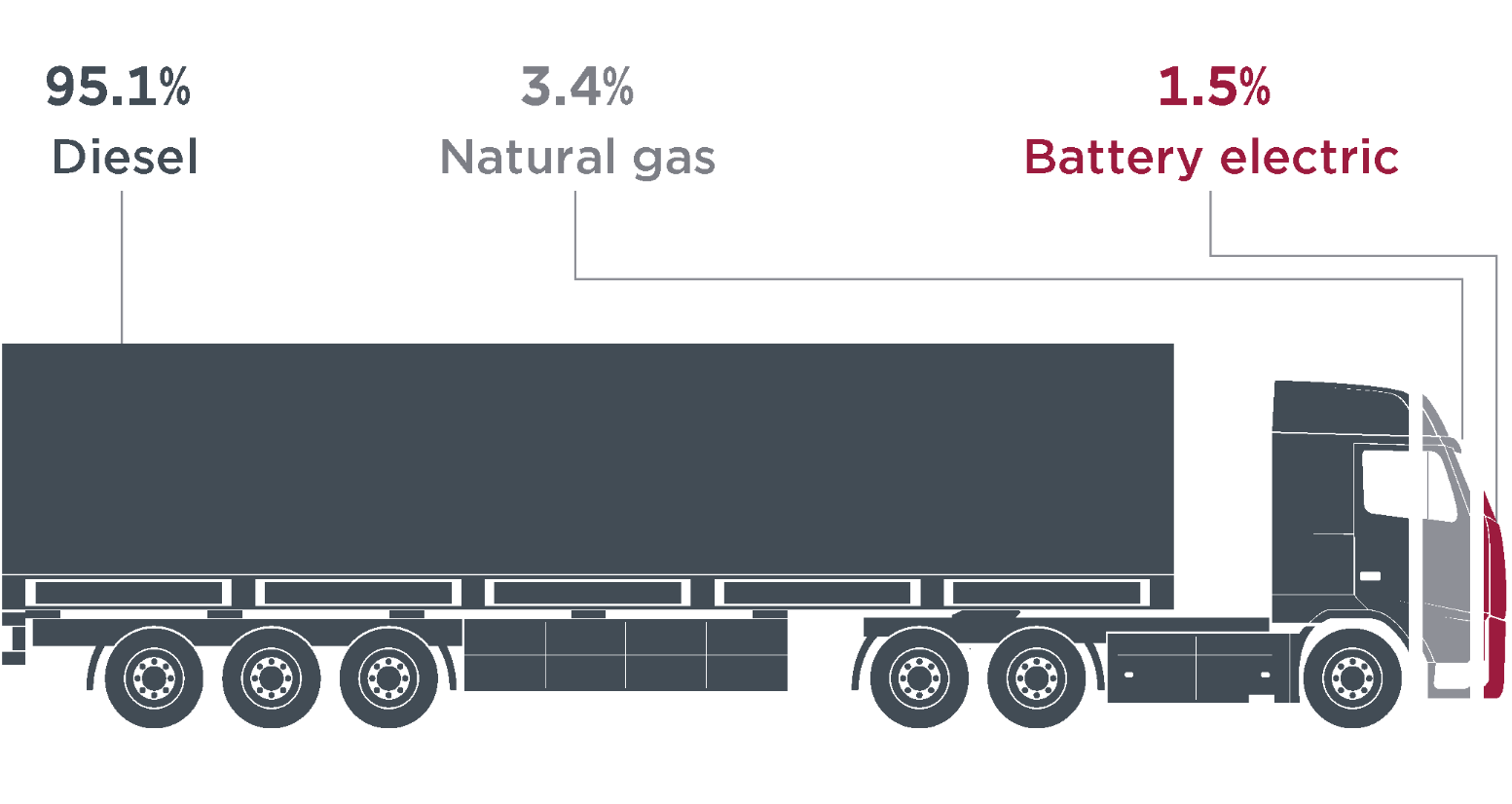

There's still a long way to go in the electrification of HDVs, with electric heavy truck sales in Q3 2025 standing at just 1.5% in Europe. (Source: The ICCT)

Working on a power project?

Our experts bring insights that extend beyond the datasheet, availability and price. The combined experience contained within our network covers thousands of projects across different customers, markets, regions and technologies. We will pull together the right team from our collective expertise to focus on your application, providing valuable ideas and recommendations to improve your product and accelerate its journey from the initial concept out into the world.

Like what you see?

Follow us on LinkedIn

Follow our dedicated power page on LinkedIn for the latest power updates and news from our team of power experts.